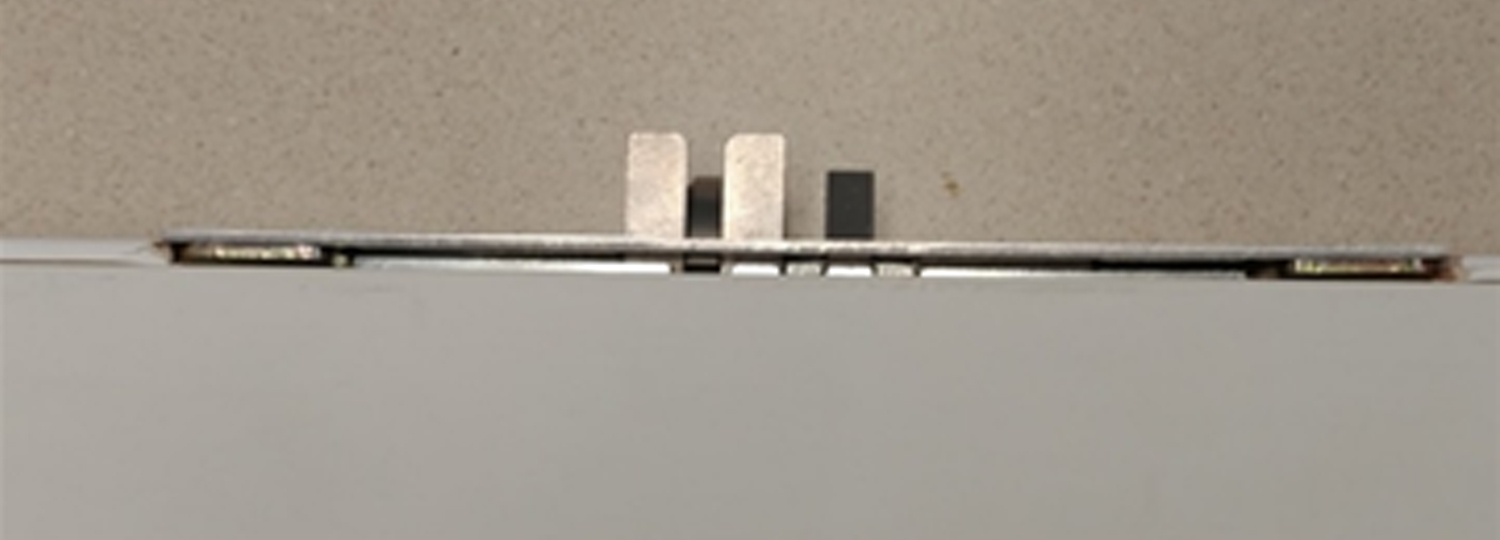

The Therma-Tru door offering comes with a Therma-Tru approved, multi-point lock. It has a relatively low profile with tongues that pivot out, or shoot bolts that extend into the sill and head jamb. This lock has a unique feature that prevents the tongues or bolts from extending when the door is in the open position, preventing damage to the frame. It is recommended to use a multi-point lock on 8 tall foot doors.

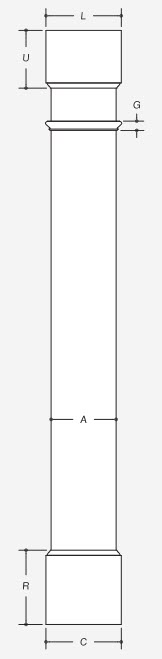

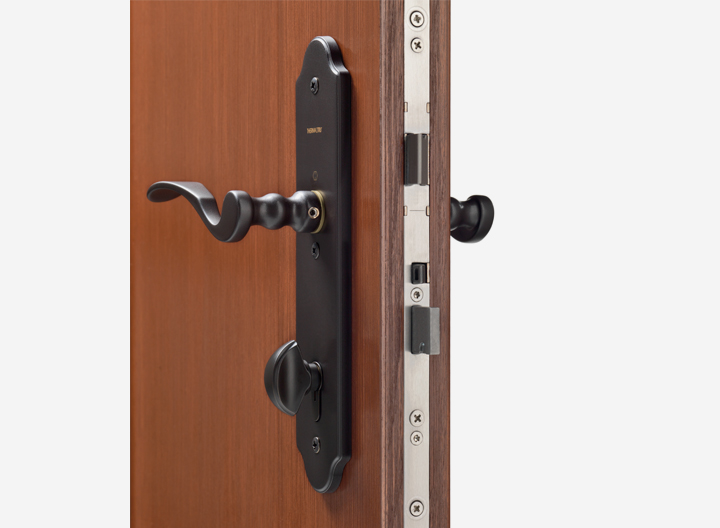

When buying a lock for a single door, the system consists of three tongues which all connect with the side jamb or mullpost. The Single Multi-Point Locking System includes Manual Tongue System Gear Box, Tongue System Top Extension, Tongue Strike Plate Package (Installed), and the Active Handle/Trim Packages (Field Applied).

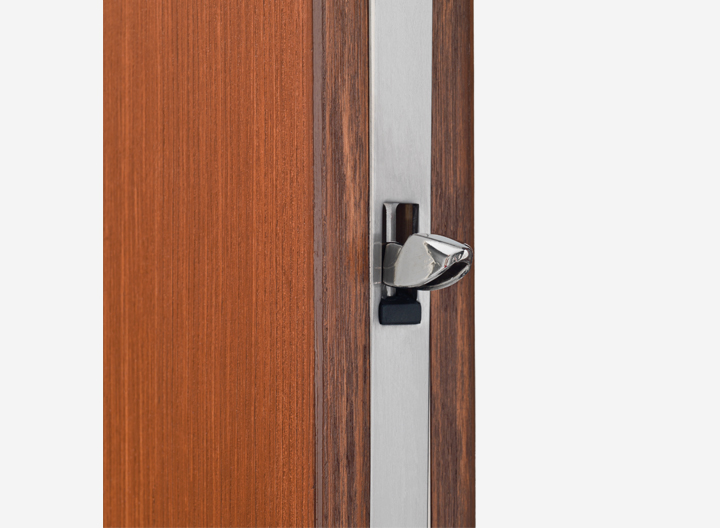

When buying a lock for a double door, the system consist of one tongue in the middle and two shootbolts – one that goes into the head jamb and one into the sill. Thr Double Multi-Point Locking System includes Manual Shootbolt System Gear Box, Shootbolt System Top Extension, Shootbolt Strike Plate Package (Installed), and the Active & Inactive Handle/Trim Packages (Field Applied).

Click here to view more information about Therma-Tru handleset functionality.