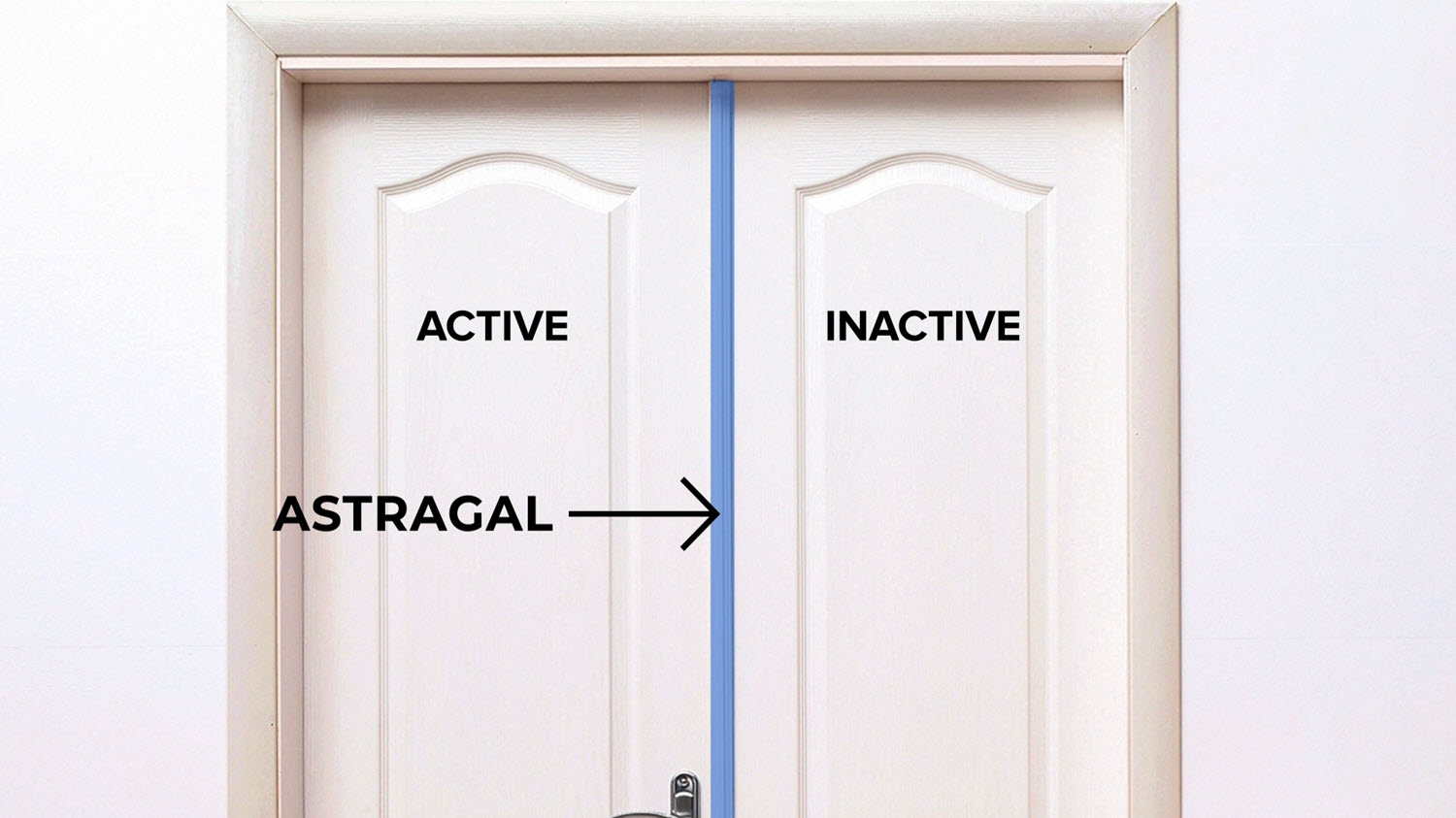

Dutch doors are a practical way to connect indoor and outdoor space, giving the perfect solution for any application and climate. Most door styles can be turned into a dutch door, as long as it has solid wood across the area to be cut, like a flush door or a door with an intermediate rail. Dutch doors are a fit for both traditional and contemporary styles.

A shelf can also be added to a dutch door which provides a stylish and practical touch. Shelves are available in any type of wood and any width to match the door. Dutch shelf installation can be a do-it-yourself project or you can order your door from an Authorized Dealer with the shelf already installed.

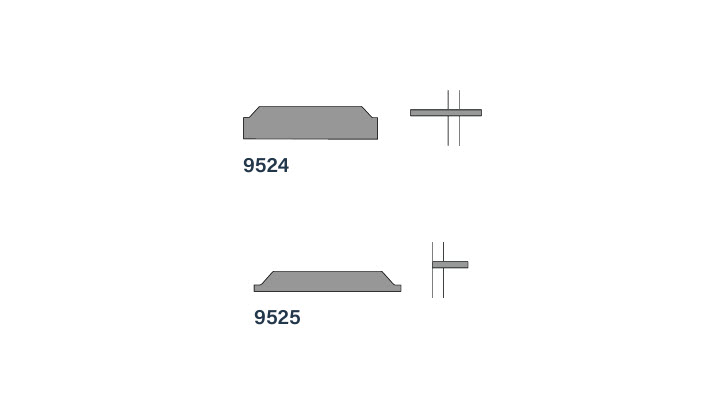

There are two options for an Interior Dutch Door Shelf which are installed on the top of the bottom section of an interior door with a straight dutch cut.

The 9524 is for an interior 1-3/8″ or 1-3/4″ thick dutch doors with a straight dutch cut that is 3/4″ thick and 8-3/4″ deep.

The 9525 is for an interior 1-3/8″ or 1-3/4″ thick dutch doors with a straight dutch cut that is 3/4″ thick and 4-3/8″ or 4-3/4″ deep.

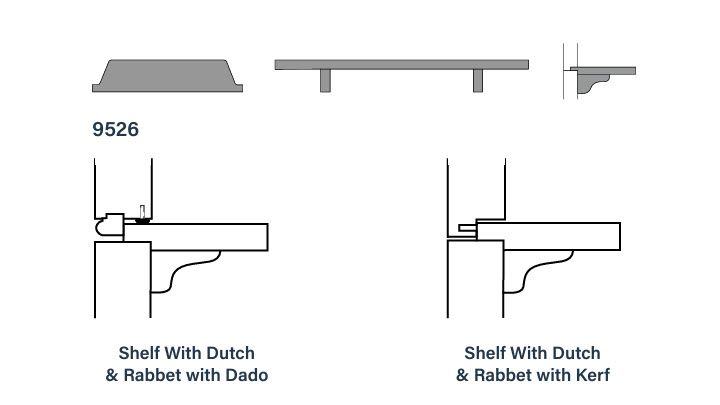

An Exterior Dutch Door Shelf would be installed on the top of the bottom section of an exterior door. The bottom of the shelf is pre-grooved to sit snugly on the bottom half of the door and the predrilled brackets support the shelf.

The 9526 is for an exterior 1-3/4″ and 2-1/4″ thick dutch doors with a cut that is 3/4″ thick and 7-1/8″ deep.

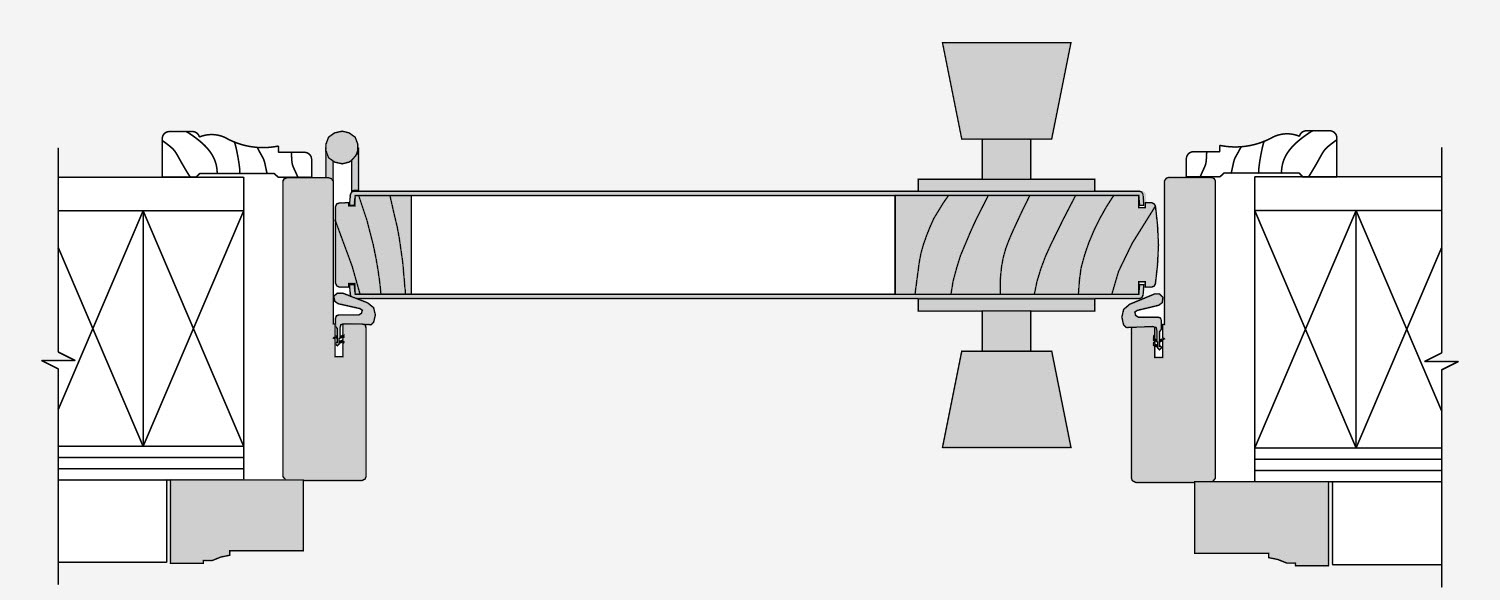

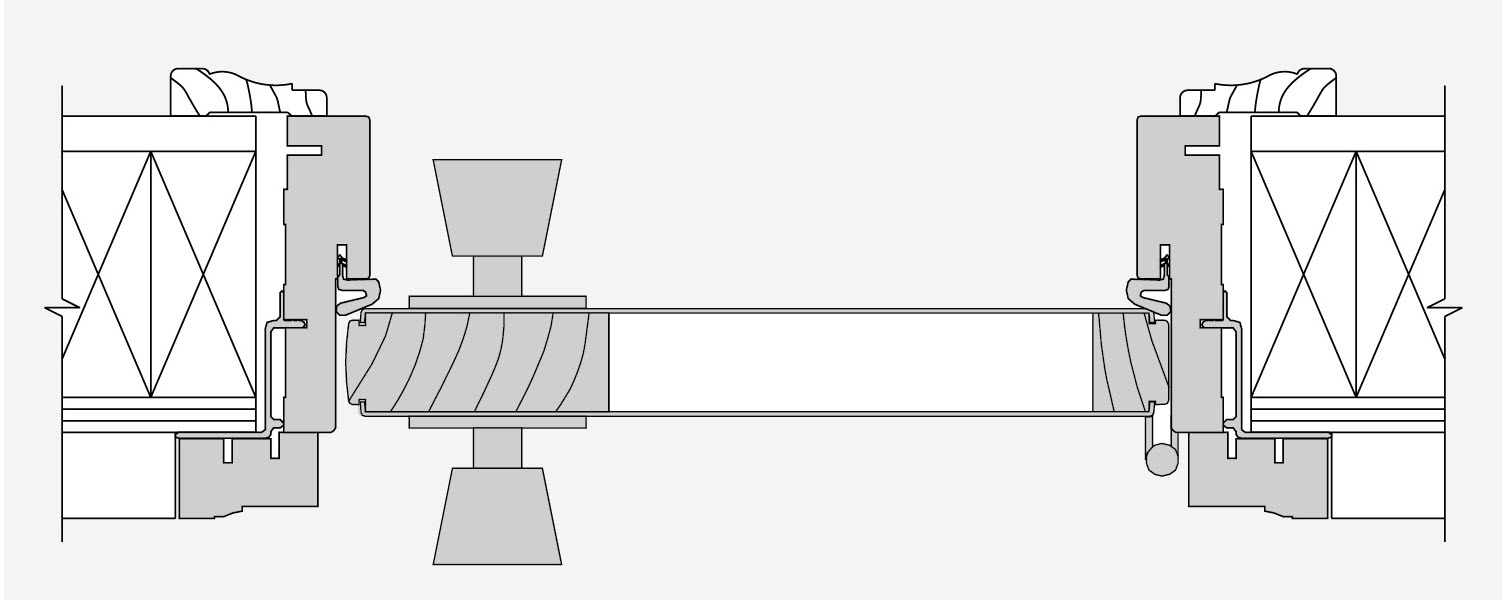

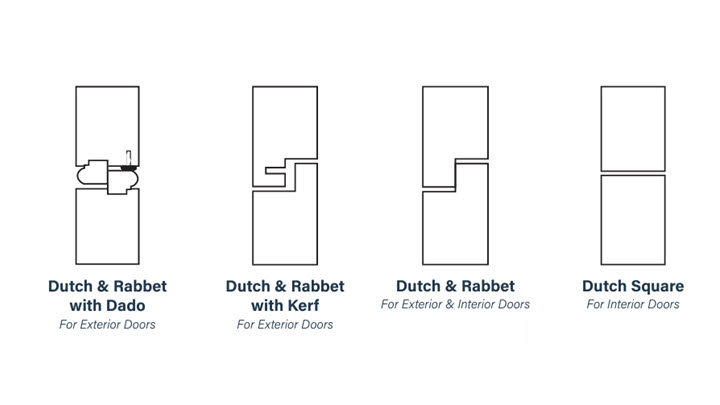

To create a weathertight seal, the top section should have either a Dutch and Rabbet with Dado cut or a Dutch and Rabbet with Kerf cut.