Fire doors are tested by the Underwriters Laboratory (UL) and Warnock Hersey (Intertek Testing Services) to ensure they withstand the necessary temperatures. In order to properly rate the door, it must be tested as a full unit with hardware. This unit is installed on a wall with a test environment behind it where the fire will burn. After the allotted time, the door unit is subjected to a fire hose test to ensure the door will hold together and the hardware will keep the door closed. The main purpose of the test is to ensure the door is able to contain the spread of the fire.

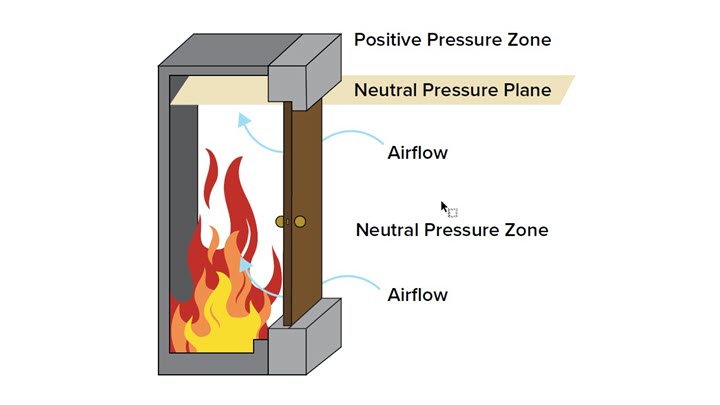

Neutral Pressure Testing

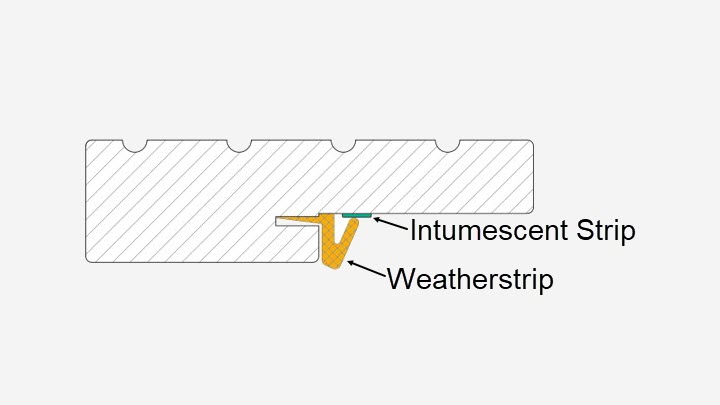

During a Neutral Pressure test, the door is installed on a rabbeted fire-rated jamb which is kerfed to hold a piece of weatherstrip. Neutral pressure assumes the pressure plane to be above the top of the door. It also assumes that pressure will not build up in the room/area containing the fire. Therefore, air from outside flows into the test room at the bottom and top of the door preventing the flames from spreading into the outside area. The use of a weather-strip/smoke seal helps to eliminate the smoke leaving the room.

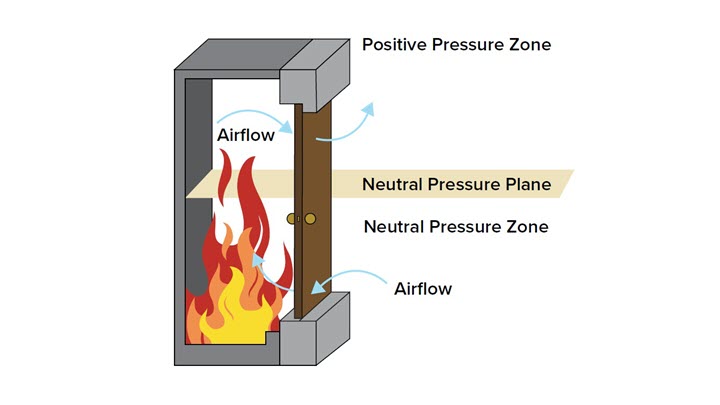

Positive Pressure Testing

During a positive pressure test, the neutral pressure plane drops down to 40” from the bottom of the door with the neutral pressure area below 40 inches and the positive pressure area above 40 inches. Air from the outside still flows into the test room at the bottom of the door. However with the pressure plane moved, air will flow out of the test room at the top. Along with the circulating air, dangerous gases and/or flames may also escape around the perimeter of the door causing the face of the door to burn in the case of wood or composite doors.

Positive pressure requires containing the hot gases and flame into the interior of the room. This is done by combining a seal such as weather-strip with an additional intumescent strip. The intumescent strip expands filling the gap at the top and sides of the door. This prevents hot gases and flames from spreading around the door. The intumescent material must be installed directly behind the weatherstrip on the head jamb as well as the side jambs. The weather-strip we install is also rated as a smoke seal.